- Home Page

- Company Profile

- Our Products

- Contact Us

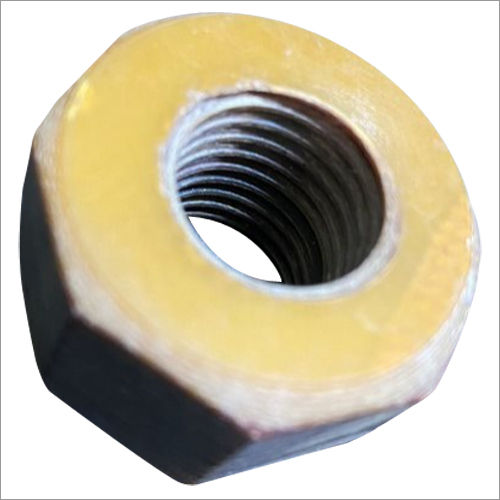

Glass Epoxy Sheet Washer

5 INR/Piece

Product Details:

- Thermal Conductivity 0.25 W/mK

- Glass Type Woven E-glass fiber

- Density 2.0 Gram per cubic centimeter(g/cm3)

- Coating Type Uncoated/standard

- Shape Washer (flat round with central hole)

- Temperature Operates -50C to +130C

- Thickness 1 mm to 10 mm (varies as per requirement)

- Click to view more

X

Glass Epoxy Sheet Washer Price And Quantity

- 5 INR/Piece

- 100 , , Piece

- >350 MPa

- UL94 V-0

- Green

- < 2 mm/m

- As per NEMA, IEC standards

- >300 MPa

- < 0.1% after 24h

- > 12 kV/mm

Glass Epoxy Sheet Washer Product Specifications

- Electrical insulation, mechanical components, aerospace, electronics, and automotive industries

- Washer (flat round with central hole)

- Molded and machined from glass epoxy sheets

- 1 mm to 10 mm (varies as per requirement)

- Fastening, insulation, support in high voltage/temperature environments

- Operates -50C to +130C

- 0.25 W/mK

- Woven E-glass fiber

- 2.0 Gram per cubic centimeter(g/cm3)

- Customizable as per requirement

- Smooth finish

- Uncoated/standard

- Glass epoxy laminate (typically FR4 grade)

- >350 MPa

- UL94 V-0

- Green

- < 2 mm/m

- As per NEMA, IEC standards

- >300 MPa

- < 0.1% after 24h

- > 12 kV/mm

Glass Epoxy Sheet Washer Trade Information

- As per client requirement.

- Asia, Central America, North America, South America, Eastern Europe, Middle East

- All India

- UL, ISO , ROHs

Product Description

| Company | Sam Associates |

| Packaging Typ | Box |

| Usage/Application | Industrial |

| Shape | Round |

| Material | FRP |

| Size | 1/2 Inch |

We manufacturer and exporter of FRP Nuts, these FRP nuts are used for industrial purpose. Including this we also offer FRP - Threaded Rods, Studs, Bolts, etc.

Advanced Material Engineering

Constructed from high-quality FR4-grade glass epoxy laminate and reinforced with woven E-glass fibers, these washers achieve an optimal balance between mechanical resilience and electrical insulation. Their smooth finish and molded or machined fabrication ensure precise performance in both standard and demanding applications across various sectors.

Versatile Functional Applications

These glass epoxy sheet washers are meticulously designed for fastening, insulation, and structural support in high voltage and temperature settings. Widely used in switchgear, electronic modules, automotive assemblies, and aerospace systems, they effectively contribute to both safety and functionality in power-dense setups.

FAQ's of Glass Epoxy Sheet Washer:

Q: How are glass epoxy sheet washers manufactured?

A: Glass epoxy sheet washers are produced by molding and machining sheets made from FR4-grade glass epoxy laminate. The sheets are reinforced with woven E-glass fibers, then cut or punched into washer shapes with a smooth finish, adhering to NEMA and IEC manufacturing standards.Q: What makes these washers suitable for high voltage and temperature use?

A: Their high dielectric strength (>12 kV/mm), low water absorption (<0.1%), UL94 V-0 flammability classification, and operational temperature range of -50C to +130C make them ideal for use in high voltage and thermal environments, ensuring superior insulation and reliability.Q: Where can glass epoxy sheet washers be applied?

A: These washers are commonly used in electrical insulation, mechanical component assembly, aerospace systems, electronics, and automotive industries-essentially wherever reliable insulation and mechanical durability are required.Q: What are the benefits of choosing glass epoxy washers over traditional materials?

A: Glass epoxy washers offer excellent electrical insulation, high mechanical strength, dimensional stability (warpage <2 mm/m), moisture resistance, and a lightweight profile, making them more reliable than standard fiber, metal, or plastic washers in demanding technological applications.Q: When should you consider customizing the dimensions of these washers?

A: Custom dimensions are advisable when specific installation spaces or unique component requirements exist, especially for specialized equipment, to ensure optimal fit, performance, and ease of assembly.Q: How are these washers typically installed in assemblies?

A: They are used as insulating spacers, fasteners, or barriers between conductive parts. Installation involves placing the washer between components to prevent electrical shorts, absorb mechanical stress, and withstand high temperatures, depending on the system requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Fiber Products' category