- Home Page

- Company Profile

- Our Products

- Contact Us

Phenolic Backlite Paper Based Sheet-P3 Grade

302.0 INR/Piece

Product Details:

- Usage INSULATION PURPOSE

- Material PHENOLIC AND PAPER

- Size Different Available

- Application For Industrial Use

- Product Type INSULATION PRODUCT

- Surface Treatment Smooth

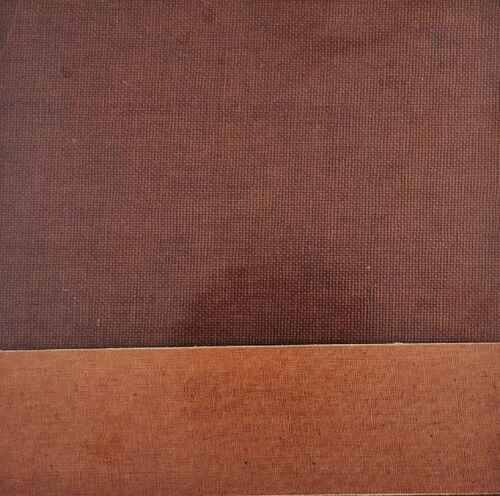

- Color Brown / Black

- Click to view more

X

Phenolic Backlite Paper Based Sheet-P3 Grade Price And Quantity

- 302.0 INR/Piece

- 300 Piece

Phenolic Backlite Paper Based Sheet-P3 Grade Product Specifications

- INSULATION PRODUCT

- Brown / Black

- PHENOLIC AND PAPER

- For Industrial Use

- Smooth

- INSULATION PURPOSE

- Different Available

Phenolic Backlite Paper Based Sheet-P3 Grade Trade Information

- Telegraphic Transfer (T/T)

- 1000 Piece Per Week

- 2 Week

- No

- AS PER CLIENT REQUIREMENT

- Asia, Australia, Central America, North America, Western Europe, Eastern Europe, Africa, Middle East

- Central India, West India, North India, All India, South India, Bihar, East India, Gujarat, Kerala, Delhi, Haryana, Madhya Pradesh, West Bengal

- ISO, REAH, ETC..

Product Description

Product Name: Bakelite Sheet P3

Brand: Tufflam P3

Size(mm):

- 1220mm x 1220mm.

- 2440mm x 1220mm.

Size (feet):

- 4ft x 4ft

- 8ft x 4ft

Thickness: 0.5 mm to 150mm

Colour: Natural Brown

Temperature : 135 degree Celsius

Exceptional Insulation Solutions

Phenolic Backlite Paper Based Sheet-P3 Grade provides superior insulation for industrial applications. Its unique blend of phenolic resin and paper ensures excellent electric and thermal resistance, making it an ideal choice for heavy-duty environments where insulation is vital.

Versatile Industrial Applications

These sheets are extensively used in electrical panels, switchboards, and mechanical setups requiring precise insulation. Their adaptable size range and reliable performance make them a preferred material for manufacturers, exporters, and suppliers across India and internationally.

FAQs of Phenolic Backlite Paper Based Sheet-P3 Grade:

Q: How is the Phenolic Backlite Paper Based Sheet-P3 Grade manufactured?

A: The sheet is produced by impregnating high-quality paper with a phenolic resin and curing it under heat and pressure. This process creates a strong, smooth material with excellent insulation properties, suitable for various industrial uses.Q: What applications are best suited for this sheet?

A: Phenolic Backlite Paper Based Sheet-P3 Grade excels in insulation applications, including electrical panels, switchboards, washers, and control equipment where durability and thermal resistance are essential.Q: When should industries use P3 Grade sheets over other materials?

A: Industries should opt for P3 Grade sheets when high electrical and thermal insulation is necessary, especially in environments with demanding operating conditions or when safety is a priority.Q: Where can these sheets be sourced in India?

A: They can be procured from leading manufacturers, exporters, and suppliers across major industrial hubs in India, many of whom offer customization options to meet specific client requirements.Q: What is the typical process for installing Phenolic Backlite Sheets?

A: Installation involves cutting the sheet to required dimensions and securing it in place using mounting hardware. The smooth surface ensures easy handling and integration into electrical or mechanical assemblies.Q: How does the material composition benefit industrial applications?

A: The combination of phenolic and paper provides robust insulation, resistance to moisture and chemicals, and maintains structural integrity under mechanical stress, making these sheets highly advantageous for challenging environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Phenolic Sheets' category