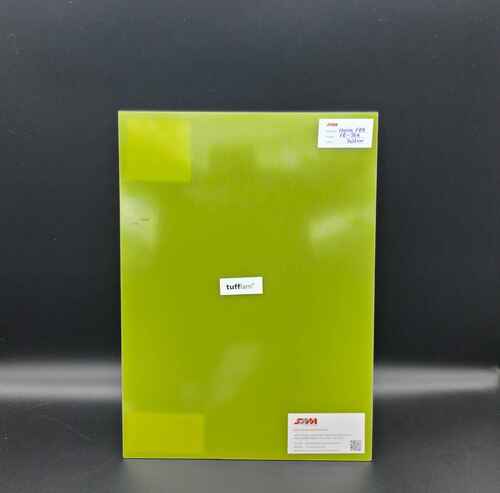

Polymide Sheet

Product Details:

- GSM Approx. 70-350 GSM depending on thickness

- Usage & Applications Used in PCB manufacturing, gasketing, sealing, and insulation for electronic devices

- Density 1.42 Gram per cubic centimeter(g/cm3)

- Coating Type Uncoated, custom coatings available

- Thermal Conductivity 0.23 W/mâ¢K

- Shape Sheet

- Temperature Operational up to 260°C, intermittent up to 400°C

- Click to view more

Polymide Sheet Product Specifications

- Casting and extrusion

- Approx. 70-350 GSM depending on thickness

- Used in PCB manufacturing, gasketing, sealing, and insulation for electronic devices

- Polyimide

- Electrical insulation, high-temperature components, aerospace, and electronic devices

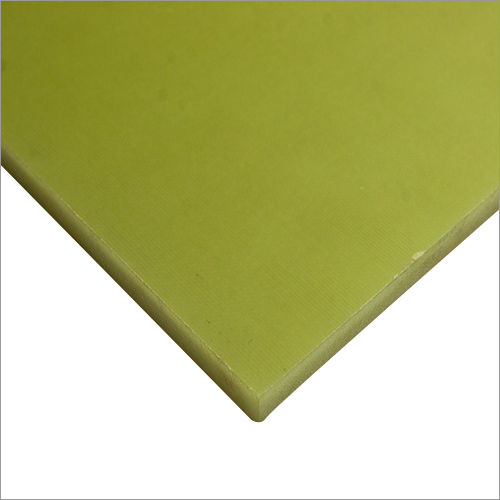

- Varies as per requirement; commonly 1000mm x 1000mm x 1mm-10mm

- 1.42 Gram per cubic centimeter(g/cm3)

- Uncoated, custom coatings available

- Smooth and polished

- 0.23 W/mâ¢K

- Sheet

- Operational up to 260°C, intermittent up to 400°C

- Available from 0.05 mm to 10 mm

- Amber

- Store in dry and cool place, away from direct sunlight

- >200 kV/mm

- 50–60%

- Carton, wooden box, or as required

- 2.8 GPa

- <1.5% (24 hrs @ 23°C)

- Excellent resistance to acids, solvents, and oils

- Customized sizes available

- 140 MPa

- V-0 (UL 94)

Polymide Sheet Trade Information

- All India

Product Description

Temperature : 220 degree Celsius

Polyimide sheet is appreciated for its flexibility, chemical resistance, and burst pressure resistance. It is utilised for medical tubing, such as vascular catheters. Our offering is a high-temperature adhesive and mechanical stress buffer used in the semiconductor sector. In addition to this, the said product is used in applications that call for tough organic materials because they have high mechanical qualities. It can be used as high temperature structural adhesives, plastics, films, laminating resins, and insulating coatings. Polyimide sheet is available in two types like thermosetting and thermoplastic. It has an outstanding mix of chemical resistance, mechanical toughness, and heat stability.

Precision Engineering for Maximum Reliability

Polyimide sheets deliver robust mechanical, thermal, and electrical properties that make them a vital material in high-temperature and high-stress environments. Whether for PCBs, gasketing, sealing, or insulation, these sheets ensure stable performance, customized to your dimensional needs.

Versatile Applications Across Advanced Industries

Our sheets are frequently employed in aerospace and electronic manufacturing, where their flame resistance, low water absorption, and chemical inertness provide significant advantages. Their adaptability to various custom thicknesses and sizes ensures suitability for a wide range of components and assemblies.

Safe Handling, Storage, and Packaging Solutions

We supply polyimide sheets in secure cartons or wooden boxes, tailored to your requirements. Storing them in a dry, cool place, protected from direct sunlight, preserves material integrity, ensuring your investment remains in top condition until use.

FAQ's of Polymide Sheet:

Q: How are Amber Polyimide Sheets typically used in electrical and electronic industries?

A: Amber Polyimide Sheets are widely utilized for insulation in printed circuit boards (PCBs), gasketing, sealing materials, and as a protective layer in electronic devices, particularly where high temperatures and demanding electrical properties are required.Q: What benefits does the V-0 flame resistance rating provide for polyimide sheets?

A: A V-0 flame resistance rating under UL 94 ensures that the polyimide sheets self-extinguish quickly when exposed to flame, offering enhanced safety for applications in sensitive environments like aerospace, electronics, and electrical insulation.Q: When should I consider using custom-sized polyimide sheets?

A: Custom-sized polyimide sheets are recommended when your project requires specific dimensions for optimal fit and performance, whether for specialized equipment, industry standards, or unique component designs.Q: Where are these sheets typically applied outside the electronics sector?

A: Beyond electronics, Amber Polyimide Sheets are found in aerospace applications, high-temperature gasketing, industrial insulation, and sealing solutions where durability and resistance to chemicals and heat are essential.Q: What is the process behind manufacturing these polyimide sheets?

A: Polyimide sheets are produced through advanced casting and extrusion techniques, resulting in smooth, polished surfaces and precise thickness control. This method ensures uniformity for consistent performance across batches.Q: How should polyimide sheets be stored to maintain their quality?

A: For best results, store polyimide sheets in a dry, cool area, away from direct sunlight. This prevents moisture absorption and potential material degradation, thereby extending product lifespan.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Glass Epoxy Sheets' category