- Home Page

- Company Profile

- Our Products

- Contact Us

Ripple Spring

463.5 INR/Piece

Product Details:

- Temperature Up to 250C

- Density 7.85 Gram per cubic centimeter(g/cm3)

- Thermal Conductivity 50.2 W/(mK)

- Coating Type Zinc Coated

- Usage & Applications Vibration Damping, Load Bearing, Cushioning

- Shape Circular / Ring

- Thickness 0.2 mm to 2 mm

- Click to view more

X

Ripple Spring Price And Quantity

- 463.5 INR/Piece

- 500 Piece

- High Load Bearing

- Box / Carton

- Silver

- Excellent

- Rust Proof

- IS 3074 / DIN 2093

- ±0.05 mm

- Cold & Hot Forged

- Long Service Life, Flexible, Reusable

Ripple Spring Product Specifications

- As per requirement

- Up to 250C

- 7.85 Gram per cubic centimeter(g/cm3)

- Spring Steel

- 50.2 W/(mK)

- Cold Rolled

- Zinc Coated

- Vibration Damping, Load Bearing, Cushioning

- Circular / Ring

- 0.2 mm to 2 mm

- Polished

- Automotive and Industrial Machinery

- High Load Bearing

- Box / Carton

- Silver

- Excellent

- Rust Proof

- IS 3074 / DIN 2093

- ±0.05 mm

- Cold & Hot Forged

- Long Service Life, Flexible, Reusable

Ripple Spring Trade Information

- Yes

- Asia, North America, South America, Eastern Europe, Middle East

- All India

Product Description

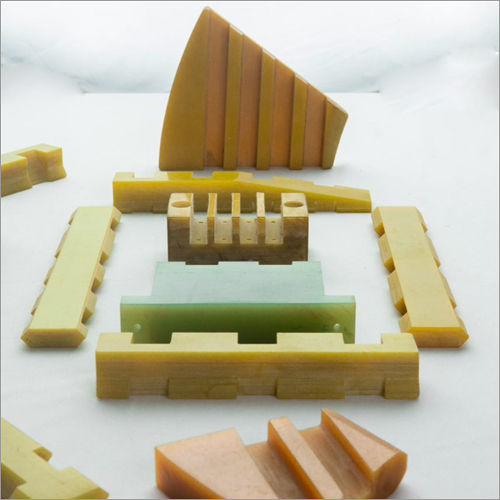

Tufflam RP 530 HRipple Spring consists of high-strength, less-weft glass cloth impregnated with modified cyanate resin, pressed under high temperature and high pressure. It possesses excellent mechanical property and anti-permanent deformability. Its permanent deformability is small at high temperature. It is used as fixed in stator slot in large generating sets .Superior Load-Bearing Capability

Engineered for demanding environments, Ripple Springs deliver high load-bearing strength while maintaining a long service life. Their unique circular or ring shape allows for efficient distribution of force and effective cushioning. This makes them particularly suited for vibration damping and support tasks in various industrial applications.

Enhanced Corrosion Resistance

Each spring undergoes thorough zinc coating and polished surface treatment, ensuring excellent protection against rust and corrosion. These properties make them reliable in harsh or humid operational environments, thereby enhancing durability and reducing maintenance frequency. The rust-proof finish meets both aesthetic and functional requirements for extended practical use.

Precision Manufacturing and Standards Compliance

Ripple Springs are produced using advanced cold and hot forging techniques, adhering strictly to IS 3074 / DIN 2093 standards. Dimensional accuracy is achieved with a 0.05 mm tolerance, tailored specifically to customer requirements. This level of precision means consistent quality and compatibility with a wide range of machinery.

FAQs of Ripple Spring:

Q: How are Ripple Springs typically used in automotive and industrial machinery?

A: Ripple Springs are primarily installed to absorb shocks, dampen vibrations, and provide cushioning under high load conditions. Their robust construction makes them ideal for supporting moving parts and ensuring stability in automotive suspensions and various industrial mechanisms.Q: What manufacturing process is used for these Ripple Springs?

A: The springs are produced using both cold and hot forging, followed by cold rolling and a polished zinc coating. This multi-step process enhances their strength, flexibility, and resistance to corrosion, ensuring optimal performance in challenging environments.Q: When should I choose Ripple Springs with a zinc coating?

A: Opt for Ripple Springs with a zinc coating when your application demands superior corrosion resistance, especially in moist or corrosive environments. The coating significantly extends the components working life and ensures reliable operation.Q: Where are these Ripple Springs manufactured and supplied from?

A: These springs are manufactured, supplied, and exported from India. They are available from reputable exporters, importers, and manufacturers who adhere to international and Indian quality standards.Q: What are the key benefits of using Ripple Springs in high-temperature applications?

A: Ripple Springs are engineered to withstand temperatures up to 250C without compromising their load capacity or structural integrity. This makes them highly suitable for demanding industrial environments where thermal stability is crucial.Q: Can the dimensions of these springs be customized?

A: Yes, Ripple Springs can be manufactured in a variety of dimensions, shapes (circular or ring), and thicknesses ranging from 0.2 mm to 2 mm, based on specific client requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Slot Wedges' category